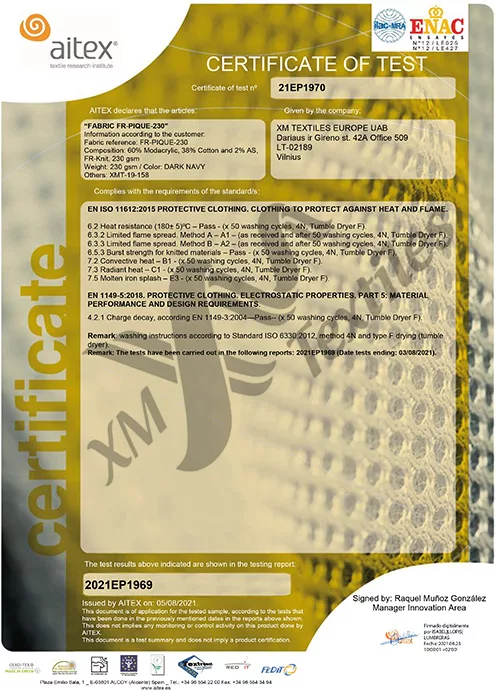

AUGUST 05, 2021 – XM FireLine fabric FR-Pique-230 has been certified by the Aitex (Spain) to EN 11612 & EN 1149 safety standards.

FR-Pique-230 is a knitted modacrylic blend with cotton and antistatic yarn. It is light, comfortable and flame retardant. Modern pique design looks very stylish on FR-clothing and allows more air circulation.

EN 11612 certification included tests for Heat resistance, Limited flame spread, Tensile strength, Tear Resistance, Convective, Contact and Radiant heat, Molten iron splash, Domestic washing 5 cycles at 60C.

EN 1149-5 is European standard for garments that protect against electrostatic discharge where there is a risk of explosion e.g. in oil refineries.

It is part of a series of standards for test methods and requirements for electrostatic properties of protective clothing.

EN 1149-3 is a test method, that uses induction charging to evaluate how fast a fabric discharge, i.e. looses its electrostatic charge via air. According to the Standard the charge decay value should be no more than 4 seconds according to test method EN 1149-3. It means that antistatic fabric should loose its electrostatic charge in less than 4s.

More information about the fabric you can find on product page.