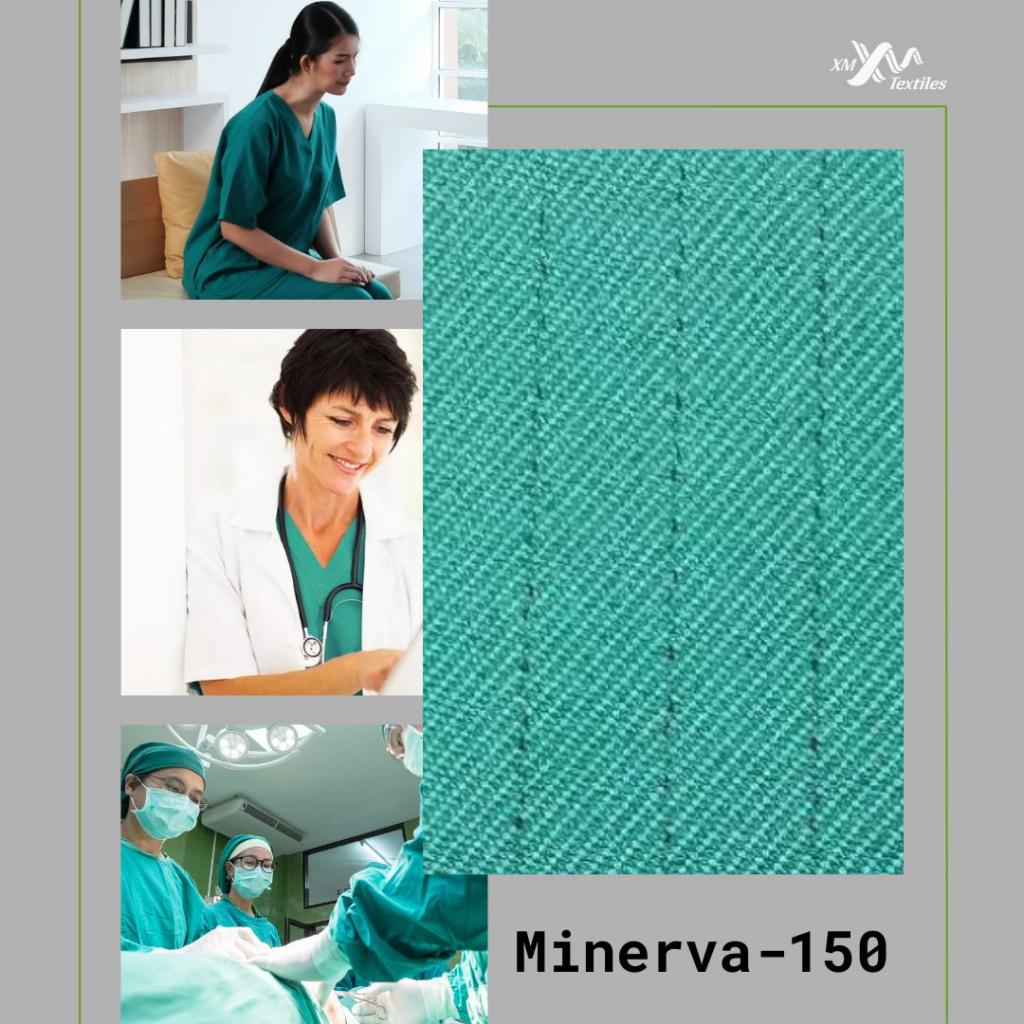

XM Textiles, a leading European supplier of fabrics for workwear and uniforms, showcased a range of over 650 products at the SAWO 2024 trade fair in Poznań. The assortment included flame retardant, stretch, and waterproof fabrics, as well as reflective tapes and sewing threads. Among the exhibits was the company’s latest development in textile materials — an antibacterial, antistatic fabric designed for healthcare professionals: Minerva-150.

Responding to a booming Polish workwear market

Driven by significant investments in infrastructure projects, workforce growth, and a heightened focus on worker safety and comfort, the Polish workwear market is experiencing dynamic expansion. According to the Mordor Intelligence report “Polish Workwear Market Size, 2023-2028,” the market is projected to reach 2.5 billion zlotys (approximately 560 million US dollars) by 2024 and witness a CAGR of 5% from 2023-2028. Key segments include construction, manufacturing, logistics & transportation, and services.

To meet market demand, XM Textiles has established a warehouse in Gdańsk, located just 100 meters from the highway and 300 meters from the port. Thanks to this strategic location, fabric deliveries across Poland take 1-2 working days.

“We ensure swift delivery across Poland within 24-48 hours, even for orders as small as one fabric roll, delivered free of charge. We closely monitor market trends, updating our assortment to meet customer demands. Our wide range of fabrics and reflective tapes satisfies the needs of sewing businesses, saving time on sourcing from multiple suppliers. With 3 new reflective tapes and 11 new fabrics introduced this year, we pride ourselves on our tailored approach to each client” —

Anzelika Syrevic, XM Textiles Head of Sales in Poland

Uncompromising quality control

XM Textiles demonstrates a resolute commitment to quality control, implementing early-stage inspections, fabric examination, laboratory testing, and international certification. Moreover, the company goes beyond standard certification for flame retardant fabrics, subjecting them to rigorous testing conducted by AITEX lab in Spain. This testing involves 100 industrial washes to verify durability and colorfastness characteristics.

Here are the top 5 fabrics with a 100-washes feature:

– POSEIDON-300 an ideal choice for industry uniforms, ensuring durability and a professional appearance

– GEFEST-480 designed for welders on offshore platforms, offers the highest level of protection against heat and flames

– VOLCANO engineered for peak performance in the oil and gas industry, protects workers in potentially hazardous environments

– FIJI good for creating comfortable and flame-resistant garments without sacrificing breathability

– ETNA the go-to fabric for workers in metallurgy, effective against heat and sparks

This ensures that even in high-risk environments such as oil and gas platforms, metallurgical plants, mines, and construction sites, the fabrics maintain their properties after extended use. In these areas, durable flame retardant fabrics are critical for ensuring worker safety and preventing injuries and material losses. Such durability provides significant cost savings for businesses by reducing the need for frequent workwear replacements, contributing to enhanced operational efficiency and safety standards. Moreover, investing in such fabrics also contributes to minimizing environmental impact.

Backed by more than 300 certificates from international laboratories like Aitex, Satra, and BTTG, along with our in-house quality control team, we ensure the quality of every batch. We also provide assistance in clothing certification, covering up to 50% of the cost and facilitating contact with major laboratories. Our flexible approach extends to product replacements or refunds, ensuring customer satisfaction

— Anzelika Syrevic, XM Textiles Head of Sales in Poland

Diverse Reflective Tape options

In XM Textiles’ range, you’ll find 45+ reflective tapes categorized by application method (sew-on or heat transferred) and meeting safety standards EN 20471 and EN 469.

SEW-ON reflective tapes are highly durable and suitable for tough work environments and industrial washes but require more effort and time to apply and can make garments heavier and less flexible.

HEAT TRANSFER reflective tapes are quicker to apply, more comfortable, and allow for greater design flexibility, but they are less durable in heavy industries and harder to repair if damaged.

SEW-ON vs. HEAT TRANSFER Reflective Tapes

| Feature | SEW-ON Reflective Tape | HEAT TRANSFER Reflective Tape |

| Application | Requires sewing, Time-consuming and requires sewing skills | Iron-on application, Quick and easy to apply |

| Fabric Compatibility | Works with various fabrics | May not adhere well to all fabrics |

| Durability | Holds strong after sewing, More durable for industrial washes and dry cleaning | Can tear if caught on something, Less durable for industrial washes and dry cleaning |

| Suitability | Suitable for tough work environments, such as manufacturing, Applicable to various fabric types | Not ideal for heavy industry (welding) |

| Flexibility | Makes garment less flexible | Softer and more comfortable |

| Design Options | Limited design options | Allows for personalized designs and logos, Possibility of cutting for “WORDS” (logos, company names, etc.) |

| Weight | Makes garment heavier | Lighter |

| Delicate Fabrics | Sewing can leave permanent holes in delicate fabrics | Can be applied to stretch fabrics and tricot fabrics, Many tapes are specifically designed for waterproof fabrics |

| Repairs | Easier to repair | Repairing damaged tape sections is difficult, often requiring removal and reapplication of a new piece |

XM Textiles at SAWO 2024

- The textile industry is undergoing a period of significant transformation. Here are some SAWO 2024 insights we’d like to share:

Multifunctional clothing

- Consumers are increasingly seeking versatile clothing suitable for various activities, from sports and outdoor adventures to work and everyday wear. This trend is driving demand for high-tech materials that offer waterproofing, breathability, and durability.

New business models

- Examples include the use of online marketplaces for selling industrial products, clothing rental services to cater to specific needs, and the development of repair and restoration services to extend the lifespan of garments and promote sustainability.

Integration of technology

- Artificial intelligence is finding applications in risk prediction and hazard identification within production lines, helping to ensure worker safety. Additionally, robots and automated systems are playing an increasingly prominent role in tasks such as fabric cutting, sewing, and packaging, enhancing efficiency and productivity.

Supply chain transparency

- Consumers are demanding greater transparency within supply chains. They are increasingly interested in knowing the origin of raw materials and the working conditions throughout the production process, emphasizing the importance of ethical and sustainable practices.

SAWO 2024 is an international event dedicated to occupational safety, fire protection, and rescue equipment. Held biennially, it is the largest exhibition of its kind in Central and Eastern Europe. It serves as a crucial platform for showcasing the latest advancements and innovations in the occupational safety and health (OSH) industry, fire protection, and rescue equipment. It brings together manufacturers, distributors, and professionals from across the globe to network, exchange ideas, and explore new solutions for enhancing workplace safety and well-being.

XM Textiles is a company specializing in the production and export of textile products for workwear and uniforms, operating in the market since 2002. With over 150 clients from 50+ countries, its manufacturing capacity is based in Shanghai, China. XM Textiles serves as a reliable partner for sewing enterprises, providing high-quality products, a wide range of services, and excellent customer service.